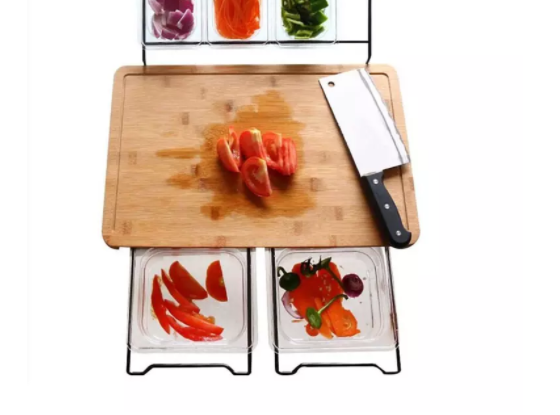

Product description

| Product name | Bamboo Chopping Board |

| Season | All-Season |

| Room Space | Kitchen, Dining Room |

| Design Style | CLASSIC, Modern, Morden Luxury |

| Color | Natural |

| Shape | Rectangle |

| Material | BAMBOO |

| Size | Different size is available |

| Usage | Kitchenware |

| Application | Restaurants Hotels Family Kitchen |

| Sample time | 1-3 Days |

| Function | Chopping Board For Cutting Food |

| Logo | Custom logo |

| Packing | Single Piece Package |

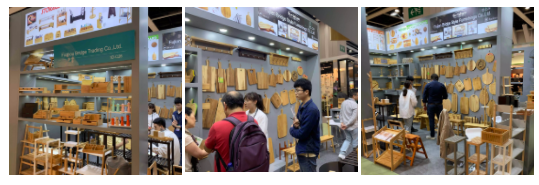

| MOQ | 500pcs |

| Feature | Sustainable |

The production process of bamboo chopping board

1. Process the raw bamboo into bamboo slices, and remove the bamboo knots on the bamboo slices;

2. Cut the bamboo slices into equal length bamboo fragments;

3. Bundle the bamboo fragments into a cylindrical bundle of bamboo slices, each bamboo slice in the bamboo slice bundle is arranged vertically according to the fiber direction;

4. Put the bamboo slice phase into the kettle, submerge the bamboo slice bundle with food wax liquid, and cook for 1.5~7.5 hours under normal pressure; when the wax is cooked, the temperature of the wax juice in the kettle is 160~180℃; when the wax boiling is completed The moisture content of the bamboo fragments in the bamboo flake phase is 3% to 8%;

5. Take out the bundle of bamboo slices from the liquid, and apply extrusion processing to the bundle of bamboo slices when it is not cold. During the extrusion processing, the bundle of bamboo slices is sequentially pressed into the cone-shaped mold and the inner cavity of the cone. The inner cavity is a cylindrical openable mold. During the pressing process, the bamboo sheet bundle enters the large diameter end of the tapered mold axially, and then enters the openable mold through the sharp diameter end of the tapered mold. The inner diameter of the rough end is the same as the inner diameter of the openable mold; before pressing into the bamboo bundle, a fastening ring is inserted in the periphery of the inner cavity of the openable mold in advance, and the bamboo bundle is compressed after being squeezed by the conical mold Into the openable mold, that is, naturally nested in the tight circle to form a product that is tightly combined between the bamboo sheets and is clamped by the fastening ring;

6. Open the mold to open and take out the above products.